Search results for piña

Refine these results

There are 99 results for this query, grouped by the following types:

- tweet 50 results

- image 32 results

- instagram 16 results

- exhibition one result

A quick weaver’s knot joins the thread; a tail that is cut off creates a single, nearly seamless thread. Hand knotting fibers together requires the utmost care so that the fibers do not break. #PineappletoPina #piña

This tweet was posted on July 25, 2022.

After the thorny strip is removed from each side, the pineapple leaf is laid upon a board and scraped to remove the pulp and reveal the fiber. Coarse white fibers called bastos are peeled away and used to make twine. #PineappletoPina #piña

This tweet was posted on July 12, 2022.

Although the Philippine Textile Research Institute began exploring ways to mechanize piña with machine-assisted fiber extraction as early as the 1970s, hand production by small enterprises still predominates. #PineappletoPina #piña

This tweet was posted on September 13, 2022.

An additional scraping of the pineapple leaf produces liniwan fibers, which are more delicate than human hair and saved to craft piña. #PineappletoPina #piña

This tweet was posted on July 12, 2022.

Anthony Cruz Legarda (b. 1963), a Filipino American fashion designer, employs Indigenous master weavers from the Philippines to create piña and piña silk fabrics for his collections. #PineappletoPina #piña

This tweet was posted on August 29, 2022.

Anthony Cruz Legarda (b.

This image was posted on August 29, 2022.

#pineappletopina #piña #pineapple #lace #fashion #design #philippines

Contemporary piña is often combined with other fibers, primarily silk (piña seda). In addition to embroidery, fabric may instead have painted or printed designs. #PineappletoPina #piña

This tweet was posted on September 13, 2022.

Craftspeople gently wash the pineapple fibers under running water or in a stream or river to prevent tangles. Any remaining pulp is removed, and the fibers are then dried in the sun. Shorter or damaged fibers are carefully extracted from the bundle. #PineappletoPina #piña

This tweet was posted on July 12, 2022.

During Spanish colonization, young Filipina women acquired a Western education at convents, orphanages, and schools that were established in cities and provinces throughout the Philippines.

This image was posted on May 10, 2022.

#pineappletopina #piña #pineapple #lace #fashion #design #phillipines

Early examples of piña exhibit high levels of intricate detail, requiring extreme patience and skill. Artisans mastered such an impressive array of styles and techniques that their works garnered praise and earned prizes in competitions from Manila to Madrid. #PineappletoPina

This tweet was posted on May 10, 2022.

Extremely fine calado entails pulling together selected fibers from the fabric to create uniform open areas in the weave; areas may then be embellished by embroidery to create a variety of geometric patterns. #PineappletoPina #piña #pineapple #lace

This tweet was posted on June 07, 2022.

Fibers are graded; historically, the finest ones were used to weave fabrics with thread counts of 320 threads per square inch.

#PineappletoPina #piña

This tweet was posted on July 25, 2022.

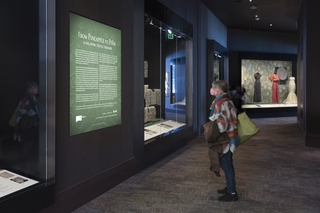

From Pineapple to Piña: A Philippine Textile Treasure

This exhibition was on display between April 2022 and November 2022 in the 1D Alley Gallery gallery, located in Terminal 1

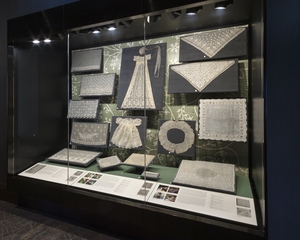

Handkerchiefs, like samplers, display an infinite variety of handwork to showcase embroiderers’ talent and skills.

This image was posted on September 27, 2022.

#pineappletopina #piña #pineapple #lace #fashion #design #philippines

His signature textile is piña, and he has played a pivotal role in incorporating the fabric into high fashion designs, including bridal gowns, women’s couture, and men’s shirts.

#PineappletoPina #piña

This tweet was posted on August 29, 2022.

Installation view of "From Pineapple to Piña: A Philippine Textile Treasure".

Image by SFO Museum. It was taken on Apr 20, 2022.

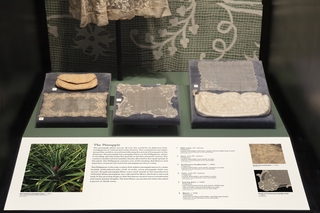

Installation view of "From Pineapple to Piña: A Philippine Textile Treasure".

Image by SFO Museum. It was taken on Apr 20, 2022.

Installation view of "From Pineapple to Piña: A Philippine Textile Treasure".

Image by SFO Museum. It was taken on Apr 20, 2022.

Installation view of "From Pineapple to Piña: A Philippine Textile Treasure".

Image by SFO Museum. It was taken on Apr 20, 2022.

Installation view of "From Pineapple to Piña: A Philippine Textile Treasure".

Image by SFO Museum. It was taken on Apr 20, 2022.

Installation view of "From Pineapple to Piña: A Philippine Textile Treasure".

Image by SFO Museum. It was taken on Apr 20, 2022.

Installation view of "From Pineapple to Piña: A Philippine Textile Treasure".

Image by SFO Museum. It was taken on Apr 20, 2022.

Installation view of "From Pineapple to Piña: A Philippine Textile Treasure".

Image by SFO Museum. It was taken on Apr 20, 2022.

Installation view of "From Pineapple to Piña: A Philippine Textile Treasure".

Image by SFO Museum. It was taken on Apr 20, 2022.

Installation view of "From Pineapple to Piña: A Philippine Textile Treasure".

Image by SFO Museum. It was taken on Apr 20, 2022.

Installation view of "From Pineapple to Piña: A Philippine Textile Treasure".

Image by SFO Museum. It was taken on Apr 20, 2022.

Installation view of "From Pineapple to Piña: A Philippine Textile Treasure".

Image by SFO Museum. It was taken on Apr 20, 2022.

Installation view of "From Pineapple to Piña: A Philippine Textile Treasure".

Image by SFO Museum. It was taken on Apr 20, 2022.

Installation view of "From Pineapple to Piña: A Philippine Textile Treasure".

Image by SFO Museum. It was taken on Apr 20, 2022.

Installation view of "From Pineapple to Piña: A Philippine Textile Treasure".

Image by SFO Museum. It was taken on Apr 20, 2022.

Installation view of "From Pineapple to Piña: A Philippine Textile Treasure".

Image by SFO Museum. It was taken on Apr 20, 2022.

Installation view of "From Pineapple to Piña: A Philippine Textile Treasure".

Image by SFO Museum. It was taken on Apr 20, 2022.

Installation view of "From Pineapple to Piña: A Philippine Textile Treasure".

Image by SFO Museum. It was taken on Apr 20, 2022.

Installation view of "From Pineapple to Piña: A Philippine Textile Treasure".

Image by SFO Museum. It was taken on Apr 20, 2022.

Installation view of "From Pineapple to Piña: A Philippine Textile Treasure".

Image by SFO Museum. It was taken on Apr 20, 2022.

Installation view of "From Pineapple to Piña: A Philippine Textile Treasure".

Image by SFO Museum. It was taken on Apr 20, 2022.